YEARS ON THE MARKET

WORKERS

CNC MACHINE

PRODUCTS PER YEAR

BORKOMET is a private family business operating in the precision metal working market. For more than 40 years now we have been offering machining services. We started our business in 1983 with products intended mainly for the fire-fighting industry manufactured with conventional machines and have been gradually transformed into a company offering high quality services provided using modern CNC machine tools.

In 2007 we moved our company from a leased building into our own, newly built bay located at 6 Przemysłowa Street in Szczekociny. Now we own a production area of 2,500 m2 including warehouse, office and social facilities.

With our experience we can offer our services to our customers in Poland, Western Europe, the United States, Canada or the United Arab Emirates. We serve companies from the following industries: petroleum industry, heat power engineering, fire-fighting, machine-building industry, railway engineering, metallurgy, medical rescue and other areas. Our commitment in the professional development of our employees, introduction of modern production machinery technologies and the measuring equipment are a guarantee of high quality of our services rendered always in due time.

Quality guarantee

Certificates

To provide our customers with products which meet their requirements we use a documented and implemented Quality Management System compliant to PN-EN ISO 9001:2015 which proves effective in a day-to-day operation.

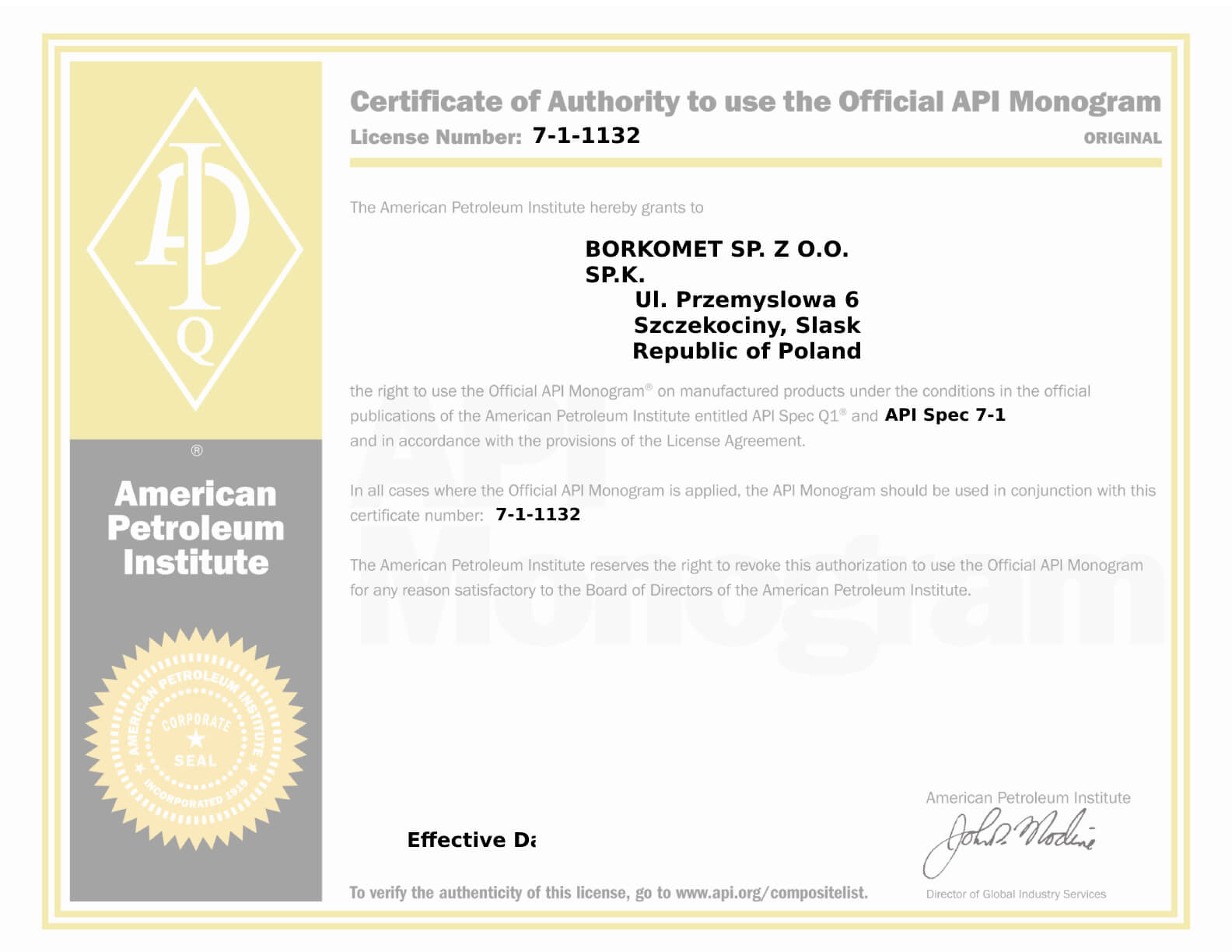

On 12 June 2014 our company, as the third entity in Poland, was certified to API Spec 7-1-1132 by the American Petroleum Institute which was equivalent to the introduction of an API Q1-compliant quality management system.

The certifications are a confirmation of high quality of both products and all the operations of planning, production and sale of the parts offered. With the advanced manufacturing technology the products supplied are always of the highest quality. All the semi-products are precisely checked by the quality control personnel at each fabrication stage. Our quality control laboratory is equipped not only with state-of-the-art conventional measuring instruments but also a Brinell and Rockwell hardness testing machine, measuring machine with the working space of 3,000 x 1,000 x 800 mm, measuring projector, height gauge. We make continuous investments in the latest measuring instruments and systems.

With our consistent strategy we can offer our customers the highest quality products and are able to take on any challenge we can face.