LATHES CNC

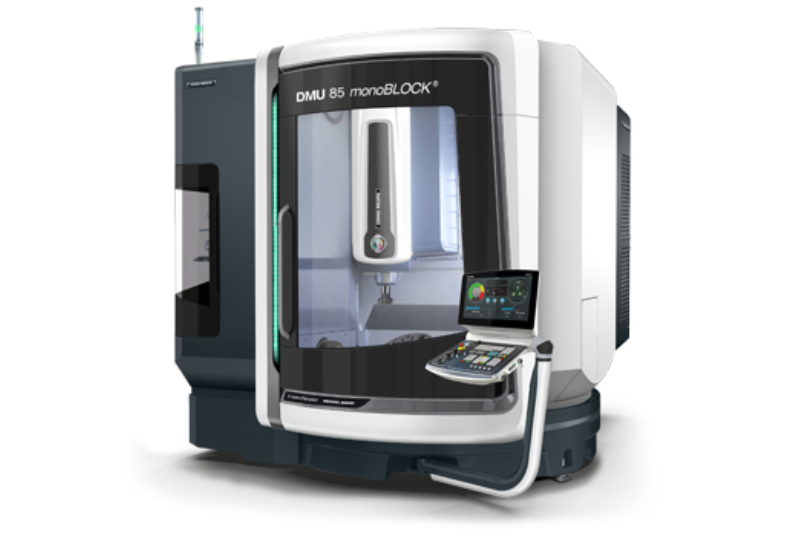

MILLING MACHINES CNC

SAWS CNC

Measuring devices

MITUTOYO HARDNESS TESTER SERIES HR-500

- hardness measurement methods: Wizhard Rockwell, Rockwell Superficial, Brinell

- loads: 29.42N, 98.07N

- super Rockwell test force: 147.1/294.2/441.3

- rockwell test force: 588.4/980.7/153.2/245.2/294.2N

- brinell test force: 61.29/98.07/153.2/245.2/294.2/306.5/612.9/980.7/1226/1839N

- adjustment of test force and hardness measurement: through the controller

- load control: Automatic (load, dwell, unload)

- dwell time: 0-120s (in 1s increments)

- max. object height: 205mm (for standard flat anvil)

- max. object depth: 150mm (from the center of the indenter shaft)

- conversion to other hardness scales: HV, HK, HRA, HRB, HRC, HRD, HRF, HRG, HR15T, HR30T, HR45T, HR15N, HR30N, HR45N, HS, HB, HBS, tensile strength

PROFILE PROJECTOR MITUTOYO PJ-A3000

- benchtop profile projector based on a vertical beam, telecentric optical system that provides distortion-free viewing on a 315 mm diameter protractor screen.

- the measuring station includes linear scales for fast and accurate linear measurement up to 1μm/.0001″, with angle measurement on the screen with a resolution of 1’/0.01° of arc.

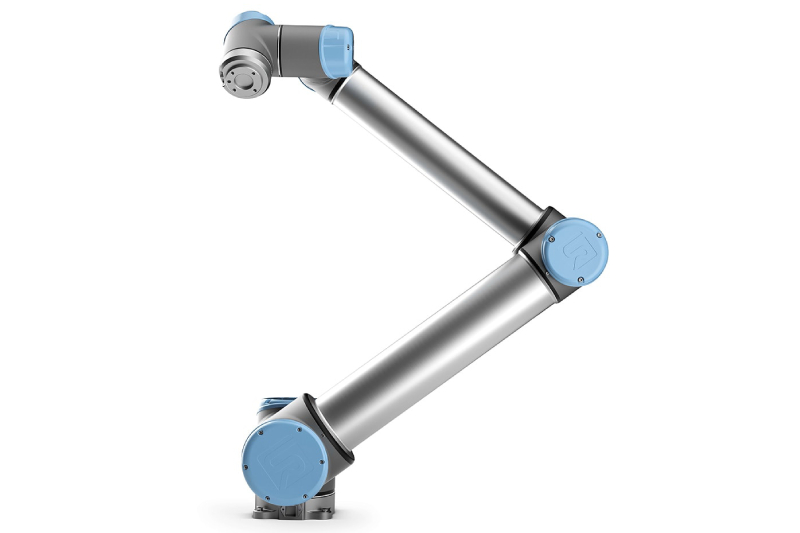

Collaborative robots

Milling CNC

.

Turning CNC

.

Deep drilling

.